LG Chem, a South Korea-based chemical company, announced plans Monday to bring a $3.2 billion electric vehicle battery manufacturing plant to Clarksville, Tennessee.

The facility will be the largest of its kind in the United States and represents the single-largest foreign investment in Tennessee’s history. It is expected to create 860 new jobs, according to a news release from the Tennessee Department of Economic and Community Development.

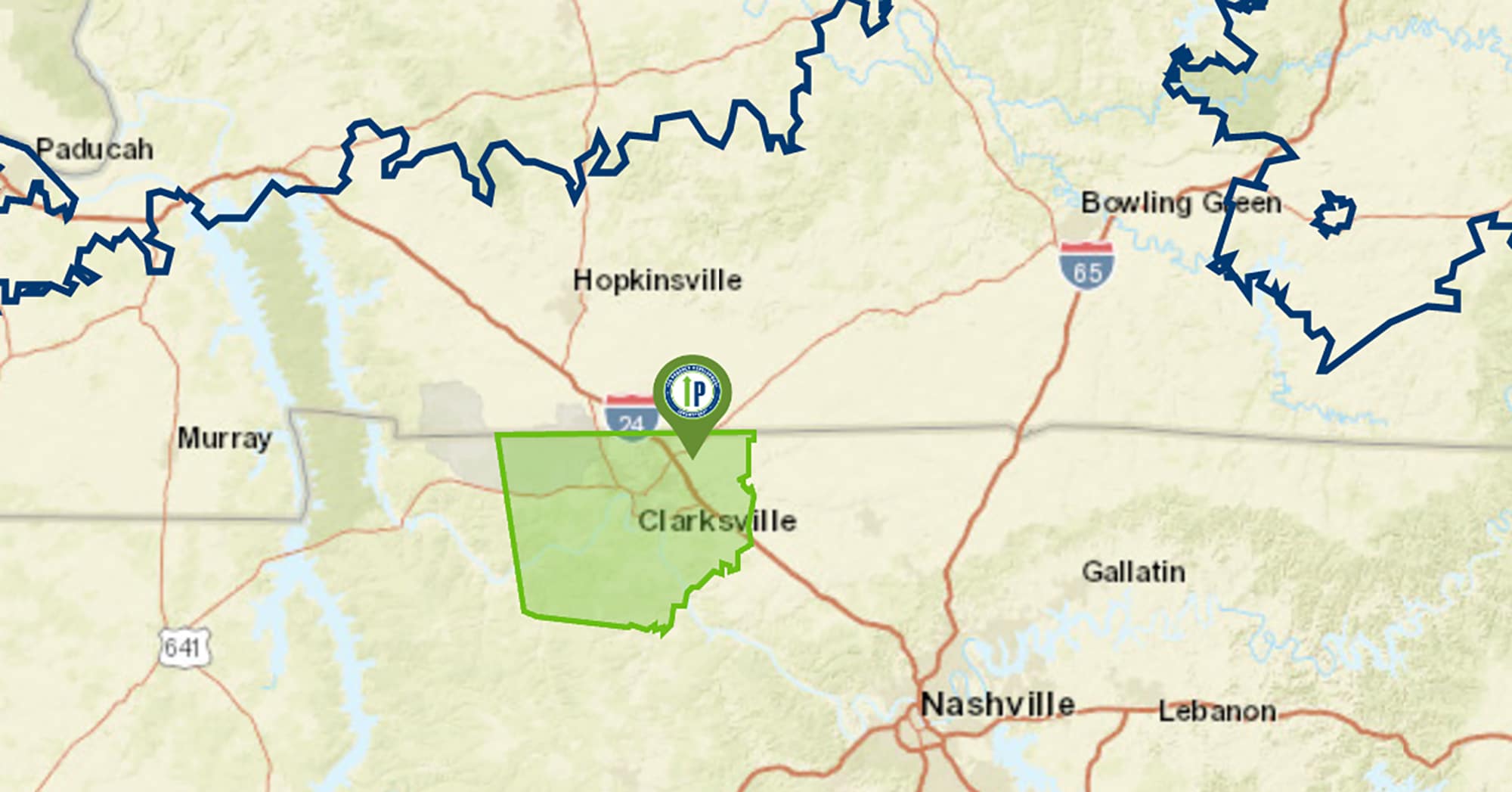

Construction is slated to begin in early 2023 at the 420-acre Allensworth Farm on Charles Bell Road and International Park Road in northeast Montgomery County — approximately 5 miles from Christian County.

According to LG Chem, it chose the location “due to its proximity to key customers, ease of transporting raw materials and active cooperation of the state and local governments.” The company noted it envisions the site being “the supply chain hub where material and recycling partners work together to supply global customers.”

The plant is expected to begin production in the second half of 2025 and produce roughly 120,000 tons of cathode material annually by 2027. That’s enough to power batteries in 1.2 million EVs with a range of 310 miles per charge.

LG Chem is the third EV battery factory announced for Clarksville in recent years.

Hopkinsville facility

This week’s Clarksville announcement comes on the heels of Massachusetts-based Ascend Elements’ groundbreaking in Hopkinsville at the site of what will be the company’s largest EV battery recycling and manufacturing facility.

The $1 billion Hopkinsville plant — located on a 140-acre parcel in Hopkinsville’s Commerce Park II — was announced in August. It will be the largest-ever economic development project in Western Kentucky and is projected to create approximately 400 jobs.

The plant, which is expected to be operational in 2024, will house the company’s innovative Hydro-to-Cathode process, a closed-loop direct precursor synthesis manufacturing system that generates no toxic waste and minimal carbon emissions. It will produce enough recycled battery precursor and sustainable cathode active materials to equip up to 250,000 EVs annually.

The company’s Covington, Georgia, facility, which currently processes “end-of-life” batteries, will eventually feed the Hopkinsville site. Ascend Elements expects to recycle more than 150,000 metric tons of lithium-ion batteries per year globally by 2026.

Growing demand for electric vehicle batteries

The EV battery industry is growing rapidly as Americans buy battery-powered cars at a record pace. According to data from Cox Automotive, EV sales jumped 70% in the first nine months of the year.

But the materials needed to produce EV batteries are hard to come by.

According to the Natural Resouces Defense Council, 50% of global lithium and cobalt reserves are in Chile and the Democratic Republic of Congo, respectively. The processing of these minerals and subsequent manufacturing of EV battery cells is also concentrated largely outside of the United States.

With the demand for the critical minerals needed to produce EV batteries is expected to grow sevenfold by 2030, the U.S. is working to stimulate its mineral production and recycling capacity — two factors experts say are key to transitioning to electric cars.

These efforts have been bolstered by incentives included in the Inflation Reduction Act and the earlier Infrastructure Investment and Jobs Act, which aim to resolve supply chain issues and address climate change by increasing the accessibility of EVs.

Among provisions included in the legislation was $2.8 billion in funding for EV battery manufacturers. Grants were distributed to 12 recipients, including Ascend Elements, which received $480 million to help develop its Hopkinsville site — elevating the local investment from $310 million to $1 billion.

Microvast, another Clarksville-based EV manufacturer, also was among the grant recipients announced in October. The company received $200 million to build a second facility in Clarksville.

Julia Hunter is the engagement editor for Hoptown Chronicle. Reach her at julia@hoptownchronicle.org.